Empowering success together

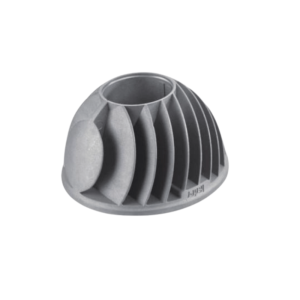

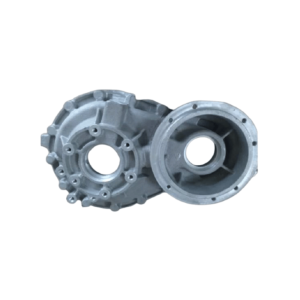

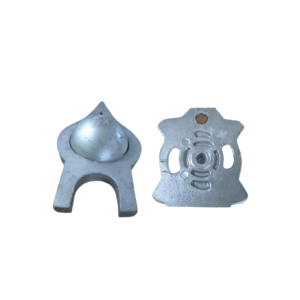

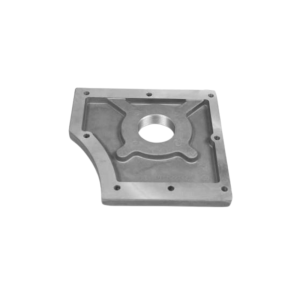

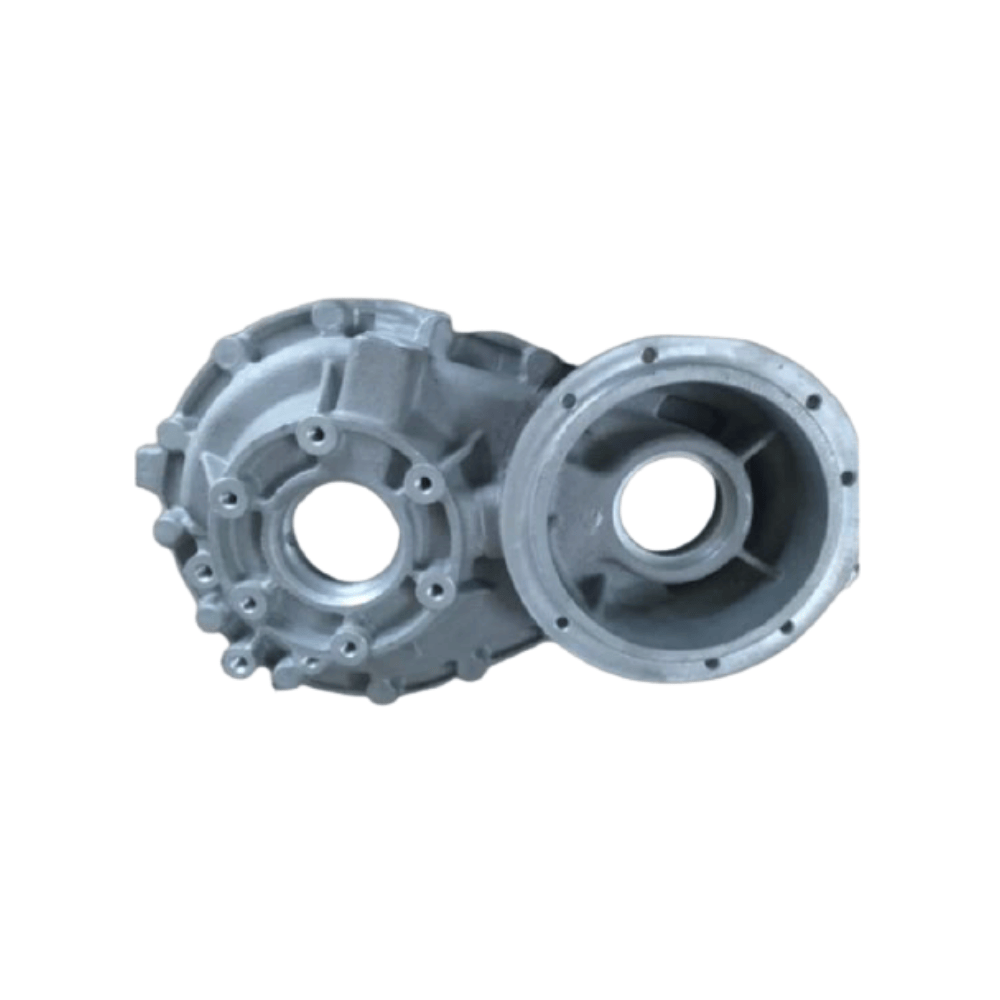

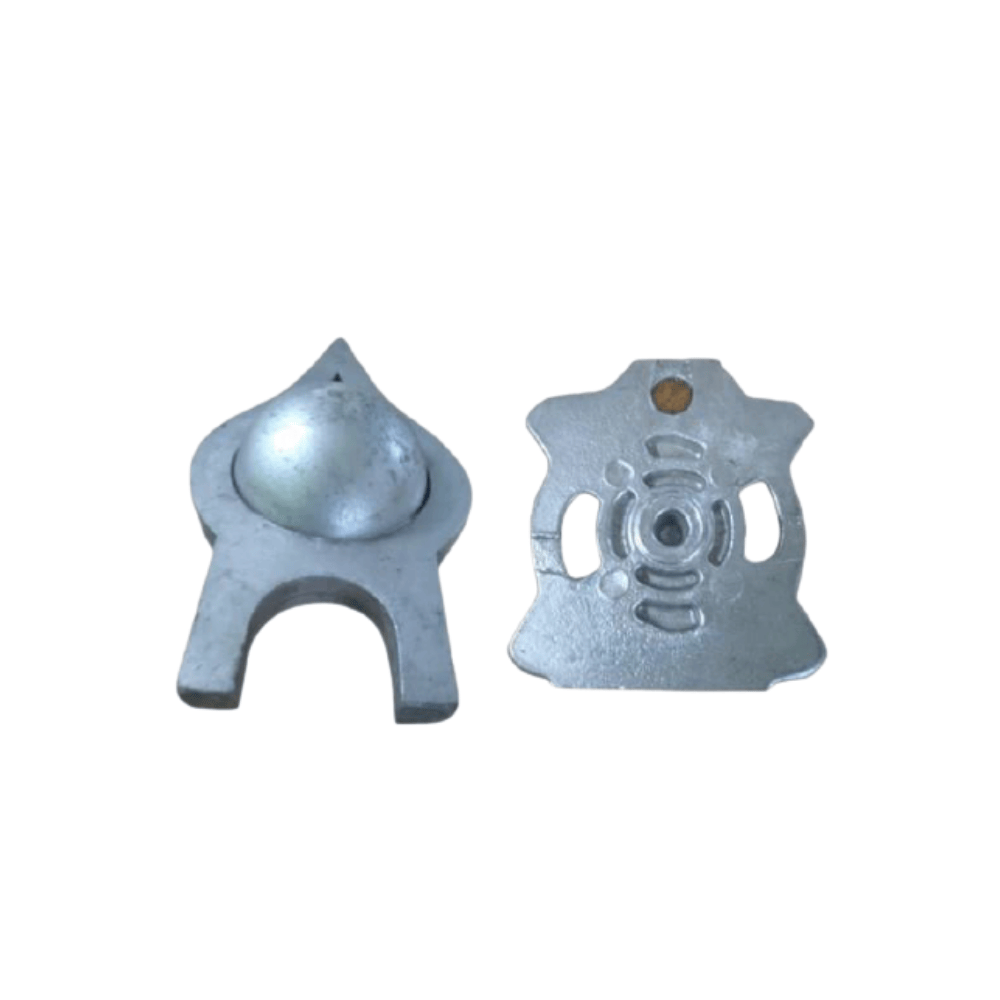

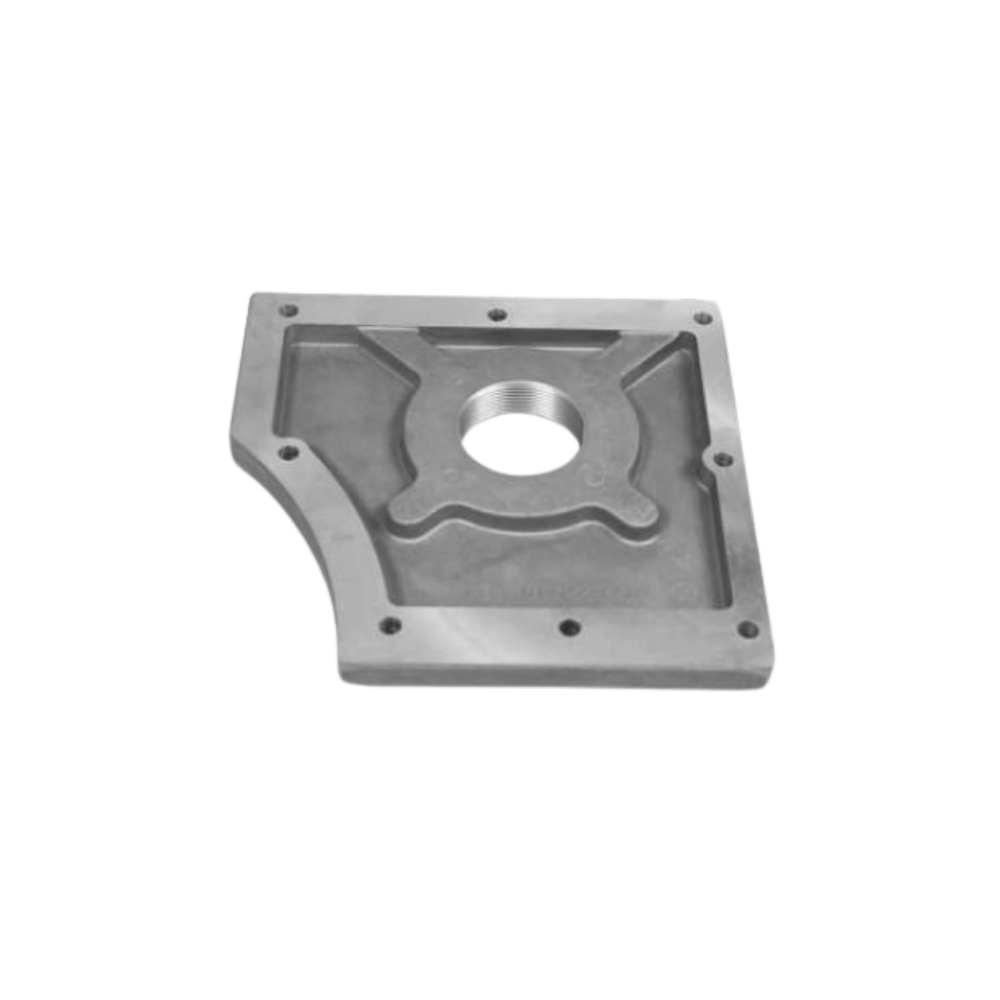

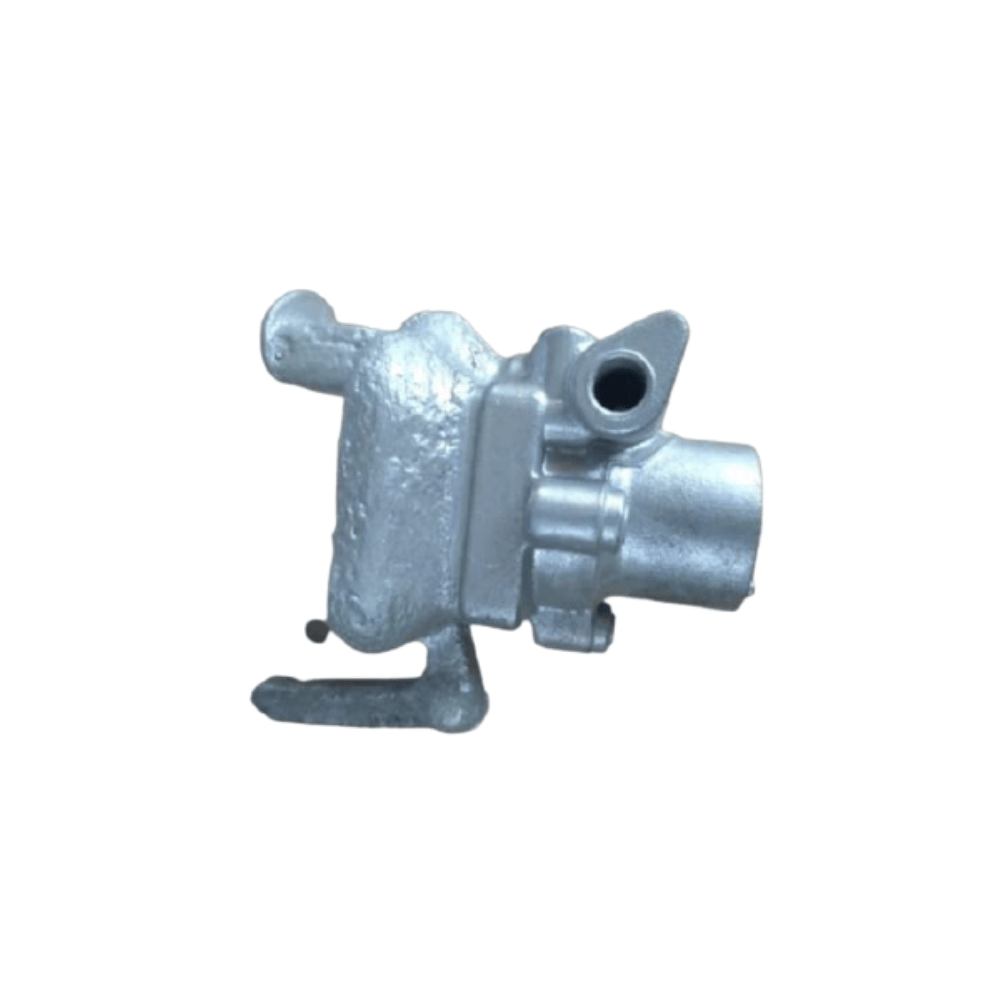

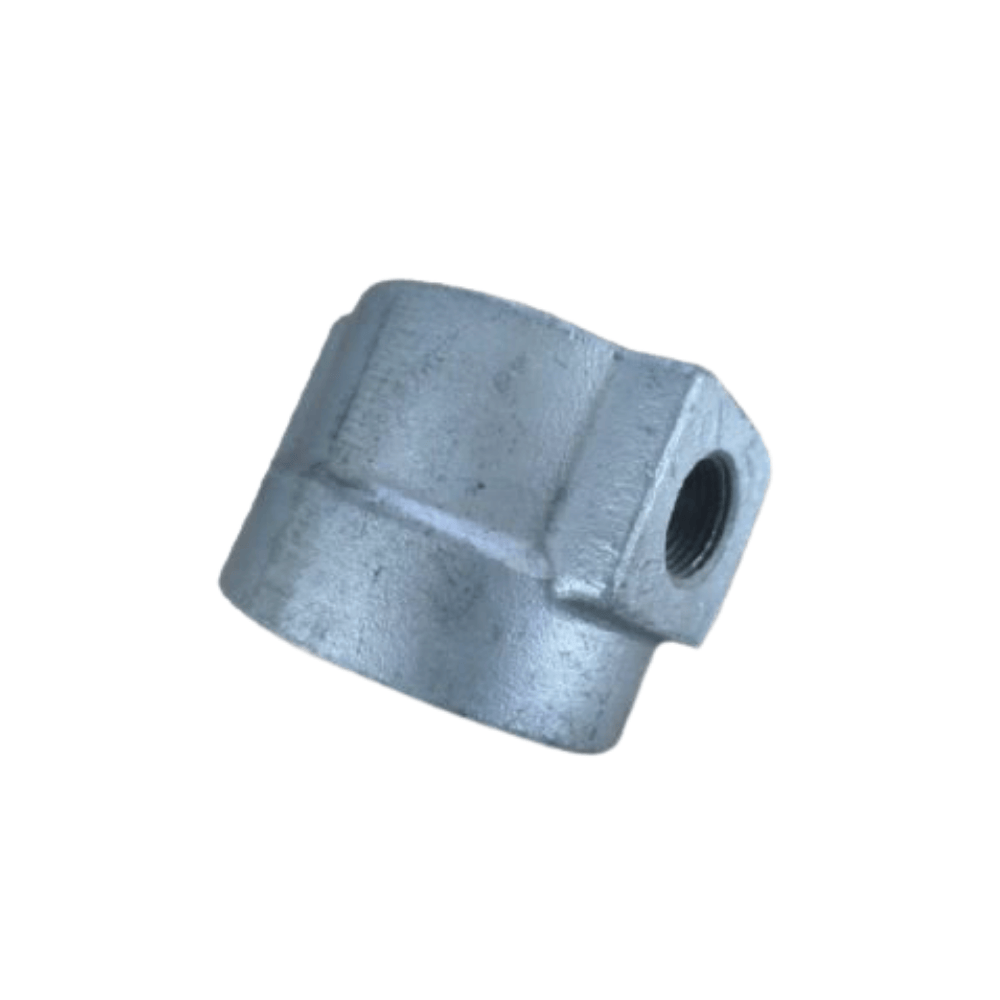

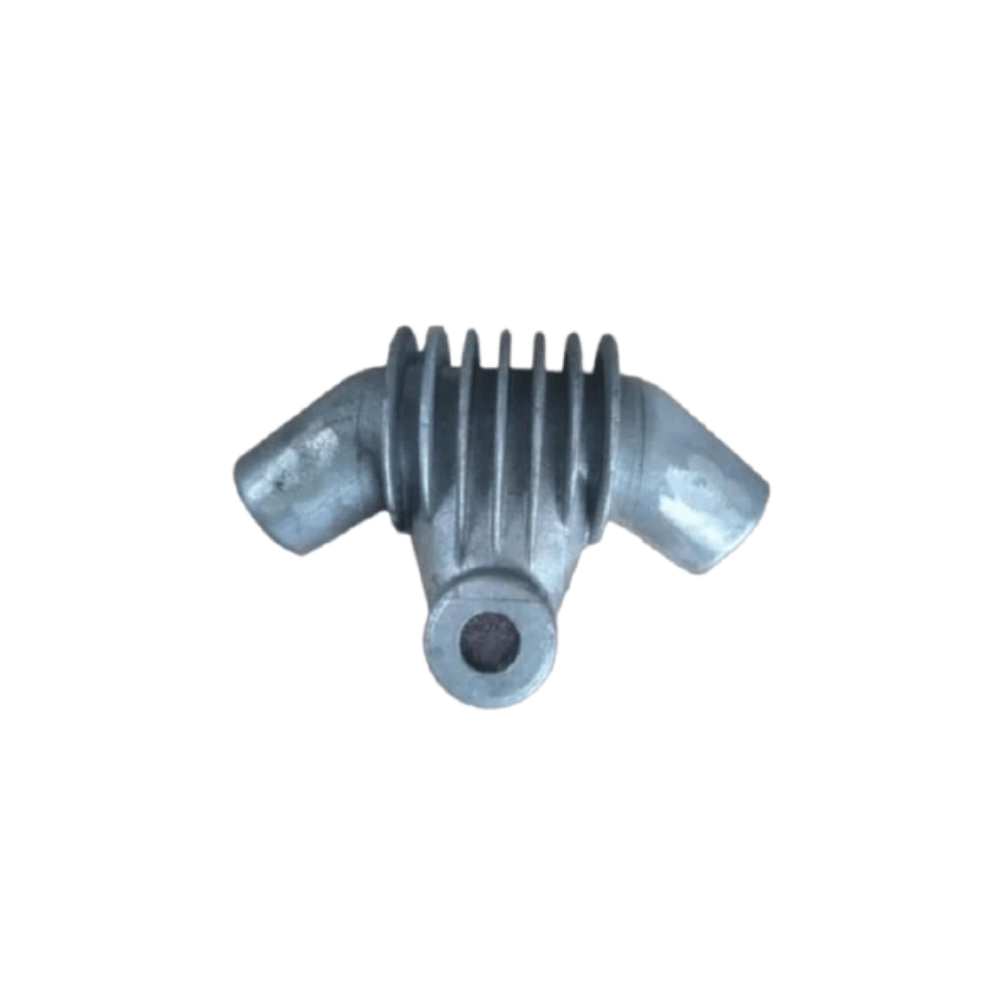

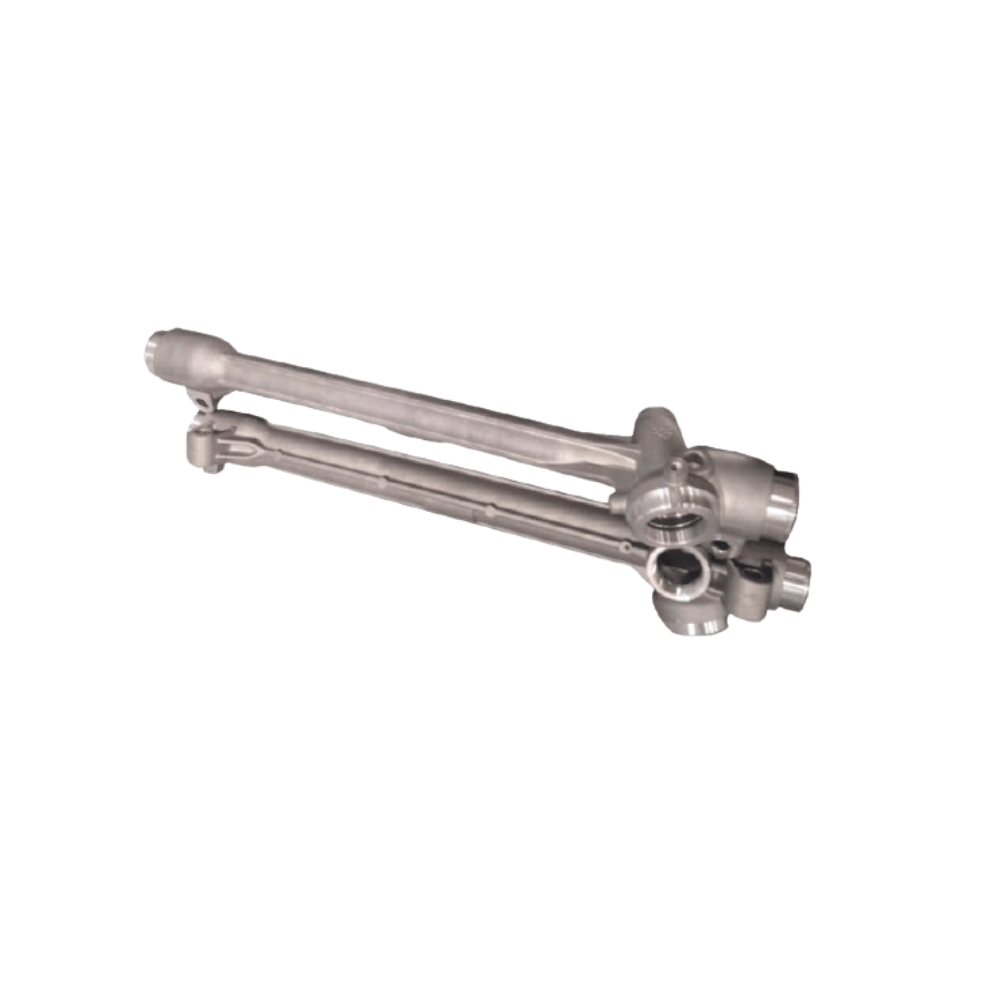

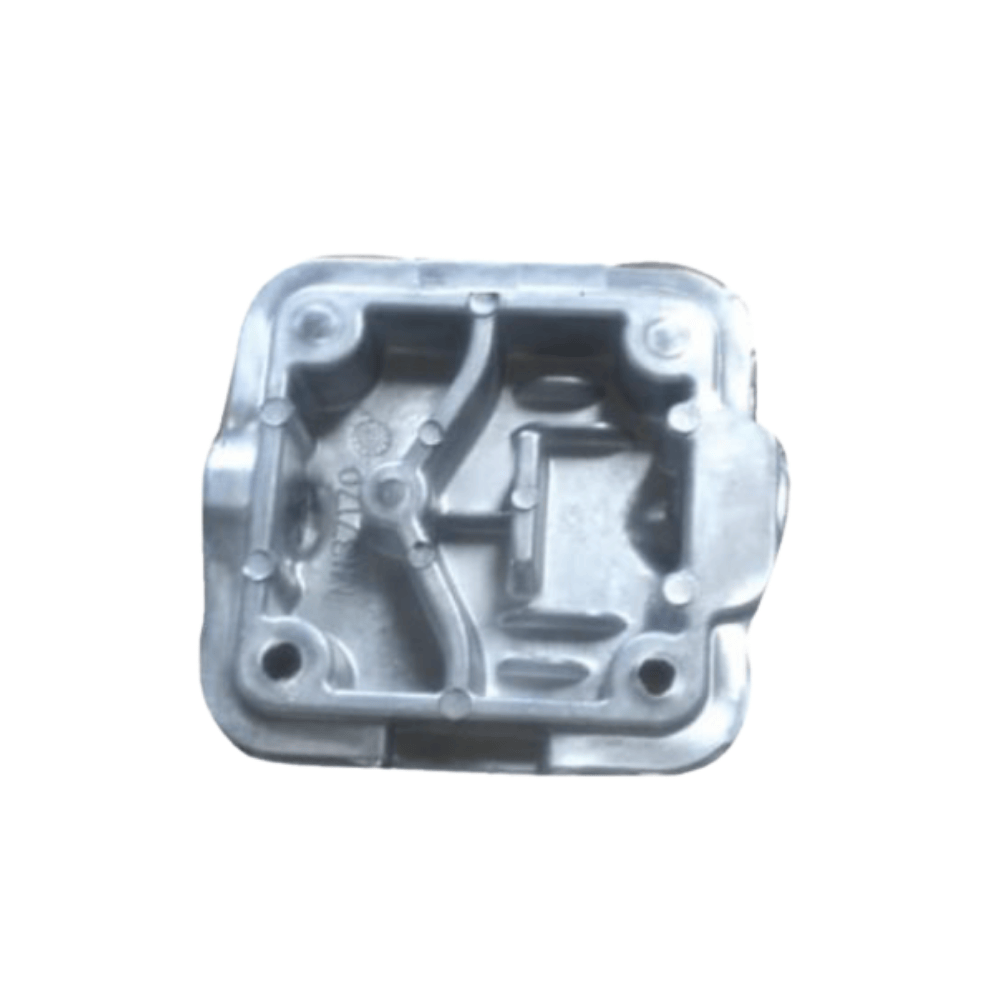

precision in every pour

excellence in every cast

your trusted partner in die casting solutions

Our Story

About Our Company and Our People

Founded with a vision of delivering unparalleled quality and precision, Sri Ayyappan Die Castings has grown from a small workshop to a leading name in the die casting industry. What began as a passionate venture focused on meeting the growing demand for high-quality metal castings has now become a trusted partner to numerous industries. Our state-of-the-art facilities, coupled with advanced die casting technology, ensure that every product we produce meets the highest standards of quality, durability, and performance.

Our team of skilled engineers and technicians work tirelessly to ensure that every product is crafted to perfection. At Sri Ayyappan Die Castings, we believe in building long-term relationships with our clients by consistently delivering high-quality products on time and within budget. Our dedication to precision, reliability, and customer satisfaction has earned us the trust among our customers. As we continue to expand, we remain focused on our core values of quality, integrity, and innovation, ensuring that we continue to remain as a leader in die casting while upholding the principles of sustainability & responsible manufacturing

Innovation-driven Solutions

Innovation is at the heart of everything we do. We are constantly evolving to meet the ever-changing needs of our customers and the industries we serve. Our commitment to innovation-driven solutions allows us to stay ahead of the curve, delivering high-quality die cast products

Personalized Approach

We leverage cutting-edge techniques, including the latest in casting machinery to optimize our processes and enhance product quality. Our team works closely with clients to develop customized and innovative solutions

Superior Customer Service

Exceptional customer service is the cornerstone of our business. We believe that building strong, lasting relationships with our clients goes beyond just delivering high-quality products—it’s about understanding their unique needs and providing personalized, reliable support

What sets apart from our competitors

Unrivaled Expertise | Our team of skilled professionals possess unmatched expertise in their respective fields, ensuring that you receive the highest level of quality and service

Personalized Solutions | We understand that every customer is unique, and we tailor our solutions to meet your specific needs, offering customized options that align with your goals

Timely Delivery | We value your time and guarantee prompt delivery of our products, thereby enabling you to stay ahead on the track and meet your deadlines on time

our in-house facilities

Frequently Asked Questions (FAQ)

What is Die casting?

Die casting is a manufacturing process in which molten metal is injected into a mold (or die) under high pressure to create precise, complex shapes. The molds are typically made of steel and can produce high-quality, detailed parts for various industries.

What are the benefits of die casting?

Benefits of die casting include:

High precision and repeatability

Complex geometries can be produced with ease

Excellent surface finishes

High production rates

Material efficiency (minimal waste)

Durability and strength of cast parts

What materials are used in die casting

Common materials used in die casting include:

Aluminum (most popular due to its light weight and corrosion resistance)

Zinc

Magnesium

Copper

Lead (less common due to environmental concerns)

Alloys of the above metals

What is the difference b/w hot and cold chamber die casting?

Hot Chamber Die Casting: The metal is kept in a chamber that is part of the machine, making the process faster and ideal for low melting point metals.

Cold Chamber Die Casting: The metal is poured into the chamber separately, allowing for higher melting point metals but requiring more time for each cycle.

Can die casting be used for custom or complex parts?

Yes, die casting is ideal for creating custom, complex parts with tight tolerances and intricate geometries that would be difficult or impossible with traditional manufacturing methods.

What are common defects in die casting?

Some common defects in die casting include:

Porosity: Air bubbles or voids trapped inside the cast part.

Cold shuts: Incomplete fusion of metal at the die interface.

Flash: Excess material around the edges of the cast part.

Warpage: Distortion or deformation after cooling.

How do die cast parts compare to other manufacturing methods?

Die casting generally offers:

Better precision compared to casting methods like sand casting

Higher production rates than methods like machining or injection molding

Lower material waste than traditional machining

How long do die casting molds last?

The lifespan of a die casting mold depends on the material used, part complexity, and the type of metal being cast. Typically, molds can last for 50,000 to 100,000 cycles or more with proper maintenance.

contact us

Phone Number

+91 9843532194

Email Id

sriayappan84@gmail.com

Address

615/1C, Eachanari main road, chettipalayam post, Coimbatore – 641050

Send Us a Message

Empowering success together

precision in every pour

excellence in every cast

your trusted partner in die casting solution

Our Story

About Our Company and Our People

Founded with a vision of delivering unparalleled quality and precision, Sri Ayyappan Die Castings has grown from a small workshop to a leading name in the die casting industry. What began as a passionate venture focused on meeting the growing demand for high-quality metal castings has now become a trusted partner to numerous industries. Our state-of-the-art facilities, coupled with advanced die casting technology, ensure that every product we produce meets the highest standards of quality, durability, and performance

Our team of skilled engineers and technicians work tirelessly to ensure that every product is crafted to perfection. At Sri Ayyappan Die Castings, we believe in building long-term relationships with our clients by consistently delivering high-quality products on time and within budget. Our dedication to precision, reliability, and customer satisfaction has earned us the trust among our customers. As we continue to expand, we remain focused on our core values of quality, integrity, and innovation, ensuring that we continue to remain as a leader in die casting while upholding the principles of sustainability & responsible manufacturing

our in-house facilities

What sets us apart from our competitors

Unrivaled Expertise | Our team of skilled professionals possess unmatched expertise in their respective fields, ensuring that you receive the highest level of quality & service

Personalized Solutions | We understand that every customer is unique, and we tailor our solutions to meet your specific needs, offering customized options that align with your goals

Timely Delivery | We value your time and guarantee prompt delivery of our products, thereby enabling you to stay ahead on the track and meet your deadlines on time

Frequently Asked Questions (FAQ)

What is Die casting?

Die casting is a manufacturing process in which molten metal is injected into a mold (or die) under high pressure to create precise, complex shapes. The molds are typically made of steel and can produce high-quality, detailed parts for various industries.

What are the benefits of die casting?

Benefits of die casting include:

High precision and repeatability

Complex geometries can be produced with ease

Excellent surface finishes

High production rates

Material efficiency (minimal waste)

Durability and strength of cast parts

What materials are used in die casting

Common materials used in die casting include:

Aluminum (most popular due to its light weight and corrosion resistance)

Zinc

Magnesium

Copper

Lead (less common due to environmental concerns)

Alloys of the above metals

What is the difference b/w hot and cold chamber die casting?

Hot Chamber Die Casting: The metal is kept in a chamber that is part of the machine, making the process faster and ideal for low melting point metals.

Cold Chamber Die Casting: The metal is poured into the chamber separately, allowing for higher melting point metals but requiring more time for each cycle.

Can die casting be used for custom or complex parts?

Yes, die casting is ideal for creating custom, complex parts with tight tolerances and intricate geometries that would be difficult or impossible with traditional manufacturing methods.

What are common defects in die casting?

Some common defects in die casting include:

Porosity: Air bubbles or voids trapped inside the cast part.

Cold shuts: Incomplete fusion of metal at the die interface.

Flash: Excess material around the edges of the cast part.

Warpage: Distortion or deformation after cooling.

How do die cast parts compare to other manufacturing methods?

Die casting generally offers:

Better precision compared to casting methods like sand casting

Higher production rates than methods like machining or injection molding

Lower material waste than traditional machining

How long do die casting molds last?

The lifespan of a die casting mold depends on the material used, part complexity, and the type of metal being cast. Typically, molds can last for 50,000 to 100,000 cycles or more with proper maintenance.

contact us

Phone Number

+91 9843532194

Email Id

sriayappan84@gmail.com

Address

615/1C, Eachanari main road, chettipalayam post, Coimbatore – 641050

Send Us a Message

Empowering success together

precision in every pour

excellence in every cast

your trusted partner in die casting solution

Our Story

Founded with a vision of delivering unparalleled quality and precision, Sri Ayyappan Die Castings has grown from a small workshop to a leading name in the die casting industry. What began as a passionate venture focused on meeting the growing demand for high-quality metal castings has now become a trusted partner to numerous industries. Our state-of-the-art facilities, coupled with advanced die casting technology, ensure that every product we produce meets the highest standards of quality, durability, and performance

our in-house facilities

What sets us apart from our competitors

Unrivaled Expertise | Our team of skilled professionals possess unmatched expertise in their respective fields, ensuring that you receive the highest level of quality & service

Personalized Solutions | We understand that every customer is unique, and we tailor our solutions to meet your specific needs, offering customized options that align with your goals

Timely Delivery | We value your time and guarantee prompt delivery of our products, thereby enabling you to stay ahead on the track and meet your deadlines on time

Frequently Asked Questions (FAQ)

What is Die casting?

Die casting is a manufacturing process in which molten metal is injected into a mold (or die) under high pressure to create precise, complex shapes. The molds are typically made of steel and can produce high-quality, detailed parts for various industries.

What are the benefits of die casting?

Benefits of die casting include:

High precision and repeatability

Complex geometries can be produced with ease

Excellent surface finishes

High production rates

Material efficiency (minimal waste)

Durability and strength of cast parts

What materials are used in die casting

Common materials used in die casting include:

Aluminum (most popular due to its light weight and corrosion resistance)

Zinc

Magnesium

Copper

Lead (less common due to environmental concerns)

Alloys of the above metals

What is the difference b/w hot and cold chamber die casting?

Hot Chamber Die Casting: The metal is kept in a chamber that is part of the machine, making the process faster and ideal for low melting point metals.

Cold Chamber Die Casting: The metal is poured into the chamber separately, allowing for higher melting point metals but requiring more time for each cycle.

Can die casting be used for custom or complex parts?

Yes, die casting is ideal for creating custom, complex parts with tight tolerances and intricate geometries that would be difficult or impossible with traditional manufacturing methods.

What are common defects in die casting?

Some common defects in die casting include:

Porosity: Air bubbles or voids trapped inside the cast part.

Cold shuts: Incomplete fusion of metal at the die interface.

Flash: Excess material around the edges of the cast part.

Warpage: Distortion or deformation after cooling.

How do die cast parts compare to other manufacturing methods?

Die casting generally offers:

Better precision compared to casting methods like sand casting

Higher production rates than methods like machining or injection molding

Lower material waste than traditional machining

How long do die casting molds last?

The lifespan of a die casting mold depends on the material used, part complexity, and the type of metal being cast. Typically, molds can last for 50,000 to 100,000 cycles or more with proper maintenance.

contact us

Phone Number

+91 9843532194

Email Id

sriayappan84@gmail.com

Address

615/1C, Eachanari main road, chettipalayam post, Coimbatore – 641050